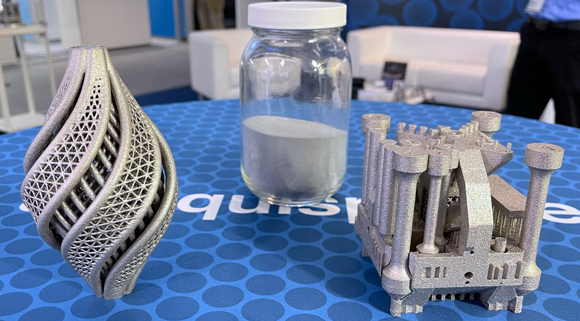

Equispheres, Inc., a leading metal powder producer in Canada, has joined the Materials Consortium established by Dyndrite, Constellium, Elementum3D, and Sandvik. Like the other members of the Consortium, Equispheres brings its unparalleled expertise to the table, committed to developing, testing, and publicly releasing parameter sets for its materials. This includes the NExP-1 line of aluminium powders designed for Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machines.

Image Courtesy - AM magazine

"We are thrilled to join the Materials Consortium alongside our industry peers. We believe that a rising tide lifts all boats and are dedicated to collaborating to provide the metal AM community with practical data that will advance the overall expertise in the processes and applications of our products," said Evan Butler-Jones, VP Product & Strategy at Equispheres.

Materials Consortium

The Materials Consortium comprises select metal additive manufacturing (AM) powder producers collaborating to create and release open parameter datasets, complete with testing data and reproducible toolpath scripts for their materials. Members concentrate on process development toolpath projects to expedite qualification. The Consortium actively strives to expand the range of usable materials, enhance productivity, and accelerate the adoption of metal AM in production environments.

Equispheres offers powders tailored for high-volume metal part production. Its advanced atomization technology, a game-changer in the industry, produces powders optimized for additive manufacturing (AM) processes, enabling manufacturers to achieve build speeds up to nine times faster than industry standards, significantly reducing production costs by up to 80%. Additionally, Equispheres' aluminium powders enhance industrial adoption by improving the mechanical properties of printed parts while increasing energy efficiency, reusability, and safety in metal AM.

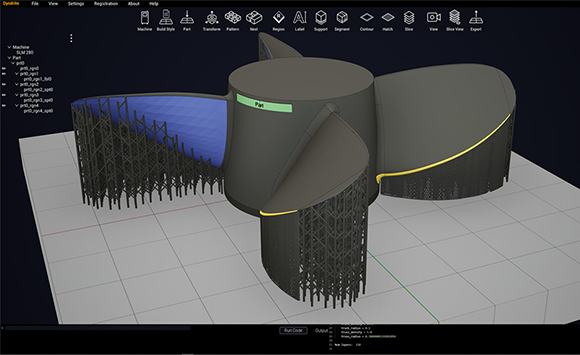

Image courtesy - Dyndrite

Fabrication of the valve component

In a recent demonstration, Equispheres and its partner Aconity3D showcased the power of their collaboration. Leveraging the advanced laser control capabilities of Dyndrite LPBF Pro, they successfully fabricated a representative valve component in 70 per cent less time than the traditional process. This new approach also resulted in improved surface roughness compared to previous software controls, a testament to the potential of their joint efforts.

"We're excited to have Equispheres join our Materials Consortium. Their commitment to empowering the additive manufacturing community with cutting-edge products that promote AM as a reliable and cost-effective manufacturing technology aligns perfectly with our mission. We eagerly anticipate their contributions to our open knowledge base, enhancing the availability of reliable and accessible parameter sets for all manufacturers," added Harshil Goel, CEO of Dyndrite.

Building on prior work with Aconity3D's 3kW laser system, the team effectively utilized Dyndrite software to reduce build time while significantly maintaining superior as-built surface quality. Employing an AconityTWO printer, the part was fabricated with bulk areas at a 120µm layer height using a high-powered beam-shaped laser, complemented by 60µm surfaces created with a 1kW Gaussian laser. This synergistic approach enhances production speed and ensures exceptional surface finishes, opening new avenues for Additive Manufacturing applications and advancements.

Responses