The new technical brief from the Aluminum Transportation Group, Drive Aluminium details three different types of cosmetic corrosion types for aluminium parts used in vehicular applications and best practices for prevention.

When properly sealed and coated, an aluminium vehicle body is inherently more corrosion resistant than an equivalent steel body. This corrosion-resistant quality is one of the reasons aluminium is a material of choice in the automotive, commercial transportation and defence industries.

{alcircleadd}

However, under specific conditions, painted or unpainted automotive aluminium can develop three different corrosion types that are primarily cosmetic. Galvanic, filiform and crevice corrosion predominantly affect surface layers only, and can influence paint retention. These types of corrosion do not penetrate through the thickness of the material and thus do not weaken the structural integrity of an aluminium part.

Galvanic Corrosion: Occurs when a metal is in contact with a dissimilar metal or a non-metallic conductor and the joint is exposed to a common corrosive electrolyte, such as salt water.

The rate of galvanic corrosion is very slow, requiring many hours of exposure to an electrolyte before visible corrosion is observed.

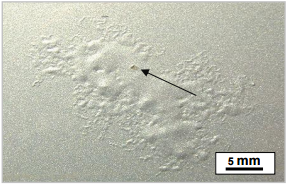

Filiform Corrosion: Occurs on the surface of aluminium under paint, primers and coatings. These type of corrosion is more common in warm and humid environments, such as coastal cities or industrial areas.

Removal of coatings and corrosion by sanding, followed by refinishing with OEM-recommended refinish materials repairs filiform corrosion.

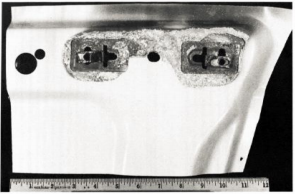

Crevice Corrosion: Occurs in a joint in contact with another material when a corrosive liquid such as salt water is present between the crevice (narrow opening) of two surface materials (aluminum, steel, plastic, etc.). Higher temperatures, salt content and other factors can accelerate crevice corrosion.

Drive Aluminium recommends cleaning surfaces thoroughly and eliminating defects (e.g., pores, mechanical damage, air bubbles, insufficient coverage, etc.) prior to finishing and coating. The association also suggests the use of OEM recommended primers, adhesives, sealers (including seam sealers), and coatings and refinish materials and the use of OEM recommended coated fasteners and insulating washers. Minimize exposure to salt water can also help in prevention of corrosion.

{googleAdsense}

For more details on aluminium corrosion, one can download the report Corrosion Types for Aluminum Parts Used in Vehicular Applications (2016) at www.DriveAluminum.org.

Responses