Hydro Extrusions recently bolstered its extrusion capabilities in Rackwitz, Germany, with the introduction of a third extrusion press line, officially operational in late 2023. This €11 million initiative encompasses the installation of a cutting-edge 22 MN, 8-inch upcycled extrusion press, complemented by an energy-efficient aging oven. This strategic investment underscores Hydro's commitment to the strong German market.

The newly integrated P22 extrusion press line significantly augments production capacity for superior-quality intricate extruded profiles. This enhancement empowers the Rackwitz facility to effectively cater to escalating demand across construction, transportation, and general mechanical engineering sectors. Furthermore, deploying this state-of-the-art line underscores Hydro's dedication to enhancing operational efficiency and sustainability, ensuring an elevated level of service for its clientele.

Since its establishment, Hydro has consistently committed to advancing and enlarging its facility. In addition to its extrusion capabilities, the plant features a cutting-edge anodising line and extensive fabrication capacities. The introduction of the anodising line in 2010 signified a pivotal achievement, elevating the site into a comprehensive, all-in-one destination for customers.

Matthias Hellmann, the Managing Director of Hydro Extrusions Rackwitz, said, “The anodising line is one of the most modern lines in Europe. We produce 2.5 million sq. m of anodised profiles per year. Besides natural anodising (C-0), we also offer colour anodising ranging from C31 to C35. We can also do piece anodising in our plant.”

Following the successful completion of the expansion project, the site now boasts three extrusion presses in operation. This enhancement has elevated production by 30 per cent, elevating it from its prior capacity of 27,000 tonnes of aluminium per year to an impressive 40,000 tonnes annually.

Hellmann added, “We currently have 250 employees and over 650 customers. The site also meets the highest safety and sustainability standards. It is Aluminium Stewardship Initiative and Environmental Product Declaration (EPD) certified and certified to EN 15088 and ISO 14001, 9001, 45001, and 50001.”

The demand for aluminium is poised for significant growth in the coming years, primarily fuelled by an increasing preference for eco-conscious solutions across various sectors such as transportation, infrastructure, energy, and food security. In the post-pandemic era, the aluminium extrusion market rebounded in almost all regions, with global extrusion usage reaching an estimated 31.5 million tonnes in 2023.

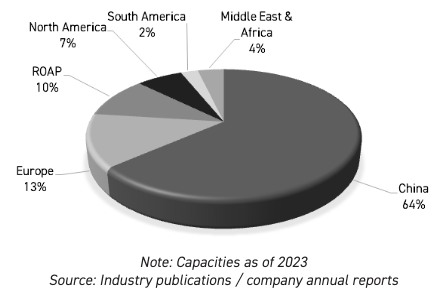

World aluminium extrusions capacity across regions, 2023

Total capacity: 49 million tonnes per annum

Explore the intricate world of aluminium extrusions and gain invaluable insights into its diverse applications across various sectors globally. Secure your copy of "The World Of Aluminum Extrusions - Industry Forecast to 2030" now to delve deeper into this dynamic landscape.

In 2023, aluminium extrusion capacity worldwide stood at around 49 million tonnes per annum. Chinese extruders accounted for about 64 per cent of this, equating to about 31.07 million tonnes. To know more, you can access "The World Of ALuminium Extrusions - Industry Forecast to 2030", your copy now to delve deeper into the nuanced landscape of aluminium extrusion utilisation across sectors worldwide.

The Rackwitz expansion initiative encompassed the installation of a repurposed extrusion press, upgraded handling systems, and a modern aging oven within an established structure, alongside various logistical enhancements throughout the facility.

Hellmann said, “We were lucky we already had space in our production hall. The space had previously been used for a press in the 1990s. More recently, it was an area for finished goods, which was moved to a new external warehouse outside the hall.”

“We have also centralized and expanded our ingot storage area and increased our packing capacity with additional stations to ensure smooth processing of finished goods and to meet the increased volume requirements.”

Hydro sourced a second-hand press from a German competitor and upcycled it for its new production line.

Hellmann stated, “We chose to upcycle the press for two reasons. First, upcycling a press goes hand in hand with Hydro’s sustainability goals. Why scrap it when you can give it a new life? Second, this was the quickest solution for implementing the concept as planned.”

Unterschütz Sondermaschinenbau GmbH, a German expert in aluminium extrusion equipment, undertook the upgrade of the press and furnishing handling systems and equipment for the entire production line. The company provided mechanical engineering expertise, project management, assembly services, and support during the commissioning of this project. The primary focus of the revitalisation efforts on the 22 MN, 8-inch press centred around modernising the hydraulic system, which Unterschütz comprehensively redesigned. Additionally, the company replaced crucial moving components and installed a new, energy-efficient container and container housing, press rest, and bolster shear.

Extrutec GmbH in Moos, Germany, undertook a comprehensive modernisation of the press feed line. They revamped the existing gas furnace alongside the press to enhance resource efficiency. Central to this upgrade was integrating Extrutec’s innovative Eco Shower Unit (ESU), a patented energy-saving technology. The ESU harnesses residual heat from the exhaust gas of the billet heater to elevate the billet temperature from ambient to 90°C. This ingenious system slashes gas consumption by 15–17 per cent while bolstering furnace throughput. An air-water heat exchanger system was also introduced, boasting a closed water circuit, automated water level control, and corrosion-resistant construction. This enhancement elevates billet furnace efficiency by a remarkable 90 per cent.

Responses