Norway's aluminium alloy ingot exports to be valued at US$1.7 billion till July 2017

Aluminium production forms the largest part of the metals industry, one of the key export industries in Norway. Norsk Hydro is the single most dominant player in the country’s aluminium sector. Headquartered in Oslo, Hydro operates the largest primary aluminium plant in Europe, in Sunndal. The Karmøy plant produces primary aluminium and rolled aluminium strip. The Årdal and Høyanger plants produce primary aluminium as well. Norway is the largest aluminium producing country in Western Europe, and almost 80-90 per cent of its output is exported to the international market.

{newsStudioGallery}

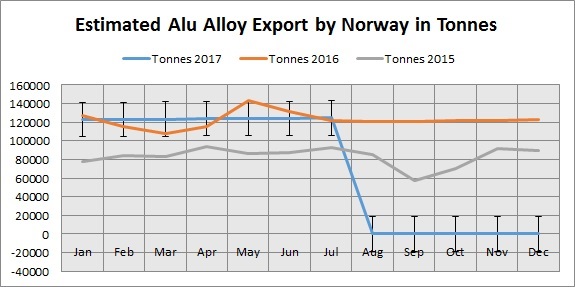

{alcircleadd}In 2015, Norway exported a little more than one million tonnes of alloyed aluminium ingot, which went up in volume by 47 per cent to reach 1.47 million tonnes in 2016. As per the latest order estimate, Norway is forecasted to ship 0.86 million tonnes of aluminium ingots (alloyed) till July in 2017. Going by the export growth rate, the total shipment volume of the commodity is estimated to remain flat as compared to the corresponding period previous year.

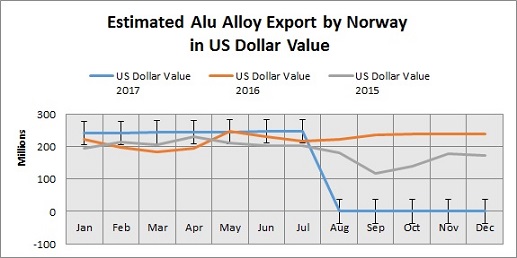

Aluminium ingot (alloyed) exports from Norway is also witnessing a value-wise growth year-over-year since the last three years. In 2015, value of the total exports of this particular product category stood at US$2.24 billion, which increased 18.3 per cent YoY to reach US$2.65 billion in 2016. In 2017, the value is estimated to reach US$1.7 billion by July, up 14.86 per cent from the corresponding period previous year.

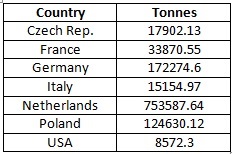

The top shipment destinations of aluminium ingots (alloy) originating from Norway are:

{googleAdsense}

In its second quarter 2016 earnings report, Norsk Hydro forecast global aluminium demand to grow by 4 to 5 per cent this year, but predicted demand from China could increase by as much as 5 to 7 per cent due to unexpectedly higher activity. According to Eivind Kallevik, CFO of Norsk Hydro, the rise in aluminium prices in 2016 was mainly due to increasing demand from the autos industry, which can use the metal to build lighter cars in order to meet carbon emissions standards.

"There's clear demand growth from the automotive side due to the fact of regulations," Kallevik said. "Whether you talk about normal combustion engine-driven cars or electrical cars, the growth factor for aluminium remains good."

The aluminium producer expects to earn healthy export revenues leveraging this increased demand for aluminium alloys in 2017 as well.

This news is also available on our App 'AlCircle News' Android | iOS